Curing differs according to the style of powder made use of. Thermoplastic and thermoset powders both equally require heat to treatment. In this article, Each and every powder necessitates publicity to a particular temperature for your set length of time to attain the desired Qualities.

A gloss finish reflects plenty of light-weight, producing shades surface far more lively and visible, whilst a matte complete diffuses mild, causing a more subdued and flat coloration look. The selection of end variety can significantly change the Visible effects of the item, based on the sought after aesthetic influence.

Powder coating comes in numerous colours and area finishes. It really is thus suited to a variety of architectural and aesthetic programs. This permits for models that include the structural energy of metals, paired Along with the aesthetic finish of any shade and texture.

Following application, the coated substrate is subjected to significant temperature curing within an oven. For the duration of this process, the powder particles soften and fuse, forming a robust and sturdy complete. The powder coating is cured in an oven at temperatures concerning one hundred ten and 250 °C. Various aspects such as heating time and substrate thickness impact the final curing time.

Infrared (IR) Ovens: IR ovens use gasoline or energy being an Vitality resource to emit radiation inside the IR wavelength band. This radiation is absorbed because of the powder and the substrate directly beneath the powder without having appreciably heating the entire component.

These resources endure plasma remedy to beat this obstacle, which makes chemically Energetic binding web-sites on the fabric’s area. Now, this surface area is wettable and hydrophilic, offering great disorders for powder adhesion.

Epoxy powder coatings are perfect for purposes that call for chemical resistance, as well as their power to remedy employing UV light tends to make them a lot quicker to apply as compared to other powder coatings.

Pre-procedure Procedure: Make certain complete cleansing and floor planning right before powder coating. Good pretreatment enhances adhesion and prevents defects.

Establish the type of material you are going to powdercoat after which you can pick out an acceptable powder for that complete. Powdercoating is done with thermoplastic or thermoset polymer powder, and these materials are formulated for bonding with distinctive base metals to provide the top success.

The hot air transfers warmth for the aspect and the coating. This can be the most common kind of oven for powder curing. Given that the component reaches the desired temperature, it conducts heat into the coating, bringing about powder curing.

The colour-shifting or “chameleon” influence, which incorporates pigments that change coloration determined by the viewing angle, makes striking visuals on objects that get noticed as colours change in numerous lights problems and Views.

Powder coating is a unique finishing las vegas sand blasting process that utilizes electrostatically charged particles that happen to be then cured below heat to form a durable protecting layer.

Removing of oil, Filth, lubrication greases, metal oxides, welding scale and so on. is vital before the powder coating course of action. It can be done by a number of chemical and mechanical strategies. The choice of the method depends on the dimensions and the material of the section to be powder coated, the sort of impurities to become taken out and the functionality requirement of the concluded product.

This elevated temperature is vital to maintain the part hotter compared to melting issue on the powder. Commonly, a traditional gasoline-fired convection oven is utilised to realize this preheating.

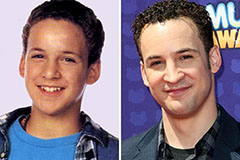

Ben Savage Then & Now!

Ben Savage Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Bernadette Peters Then & Now!

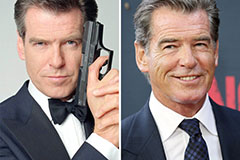

Bernadette Peters Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!